Founded in 2021, Warp has already carved a niche for itself in the logistics sector by focusing on streamlining shipping supply chains and reducing costs through its tech-enabled network of shippers, carriers, and warehouses. But the company’s latest venture into robotics to automate its network of warehouses is setting a new standard in warehouse efficiency and operation.

The Driving Force Behind Warp’s Robotic Endeavor

According to Daniel Sokolovsky, CEO and co-founder of Warp, the company continually seeks innovative solutions to enhance shipping efficiency for its clientele, which includes large enterprises like Walmart and HelloFresh. With advancements in artificial intelligence paving the way, Warp identified significant opportunities for automation within its warehouses.

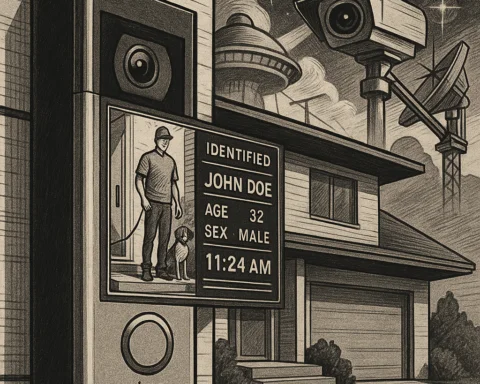

Sokolovsky mentions that while long-haul trucking and short-range delivery automation remain complex endeavors, the workflows inside warehouses can undoubtedly benefit from increased automation. Warp initiated its project by integrating cameras into its Los Angeles test warehouse, thereby creating a digital twin, a virtual simulation used for investigating and optimizing warehouse processes.

Initially, their attempts to leverage humanoid robots with traditional pallet jacks did not pan out successfully. However, Warp soon found success by retrofitting off-the-shelf robots with additional technological enhancements. This strategic pivot marks a significant step forward in adapting existing technology to solve complex logistical problems with simplicity and efficiency.

A New Era of Warehouse Automation

Robotics in warehouse settings is redefining the very idea of efficiency and productivity. By breaking down logistics problems into manageable components, Warp introduces robotics and AI in order retrieval and inventory management, eliminating the need for excessive human labor. This transition not only lessens labor costs but also makes the warehousing process far more reliable and scalable.

Co-founder and CRO Troy Lester pointedly notes that the labor currently performing these warehouse jobs often lacks fulfillment due to the repetitive or monotonous nature of the tasks. Thus, introducing robotic kits offers warehouse partners a significant edge, facilitating their operations even beyond Warp’s network.

Financial Backbone and Future Prospects

With the backing of a $10 million Series A funding round led by Up. Partners and Blue Bear Capital, Warp is set to deploy several different robotic models in multiple warehouses across key locations such as Los Angeles, Chicago, New Jersey, Dallas, and Miami. The introduction of these technologies positions Warp to maintain a competitive advantage by limiting these innovations to its core network, at least initially.

Warp doesn’t just dabble in automation; it effectively combines robotics with a well-established logistics ecosystem, creating a robust framework designed to service its customers more effectively. Unlike companies that focus solely on robotics or AI, Warp integrates these innovations to boost its logistics services, continually developing and refining systems tailored to meet and exceed customers‘ needs.

Unveiling the Broader Landscape of Warehouse Automation

According to NetSuite’s insights on warehouse automation, integrating technology in warehouse operations spans systems automation, mechanized automation, and advanced warehouse automation. While these stages represent varying complexity levels, from conveyors to AI-operated robots, the ultimate aim is to minimize human error, boost operational efficiency, and ensure consistent output regardless of demand fluctuations.

Flexibility is a key trait defining advanced warehouse automation, evident in Warp’s approach to customizing robots for specific tasks and environments. Similarly, predictive analytics and machine learning algorithms, as discussed by additional articles, offer predictive maintenance capabilities and forecasts that are invaluable for inventory management.

Robotics and AI: The Future Predicted

The potential benefits of such technological investments are manifold. Automated warehouses increase throughput, improve resource allocation, and significantly enhance operational safety. While installation costs are high, the ultimate return on investment includes not only reduced labor costs but also reduced warehouse handling and storage costs. Furthermore, predictive analysis and enhanced inventory control through AI and ML can greatly improve customer satisfaction by ensuring timely and accurate order fulfillment.

As for Warp, the journey towards an entirely autonomous network of warehouses is not just visionary but in many ways achievable. With each new iteration of robotics and AI, Warp is set on a path not just to automation but to crafting intelligent, self-regulating supply chain networks that stand resilient against disruptions, adapt to fluctuations, and deliver unmatched efficiency.

Conclusion

Warp’s foray into robotics marks a new chapter in warehouse management, promising competitiveness through innovation. By steering their operations towards automation backed by AI insights, Warp is poised not just to meet but shape the future demands of the logistics industry. This evolution, echoed across the wider industry through similar technological ambitions, underscores a pivotal moment for logistics — one where machine intelligence and human foresight blend seamlessly to deliver unprecedented operational excellence.